SEM676D Wheel Loader

- Model

- SEM676D

Item specifics

- Operating weight

- 23000kg

- Bucket capacity

- 4.2-7.0m³

- Engine power

- 199/2200kW/rpm

- Minimum Turning Radius Over Bucket

- 7790mm

- Origin

- China

Review

Description

SEM676D

The SEM676D wheel loader can be widely used in ports, mines, steel mills and large construction sites to provide efficient and fast solutions;Especially suitable for loading and transferring loose materials such as iron ore powder, coal and sand and stone.

Easy to Operate

- FNR (Forward-Neutral- Reverse) controller and KD (Kick Down) button integrated on pilot control, which makes operation easier

- 2nd-4th automatic gearshift and E-control automatic leveling function improve operating efficiency and comfort

- World-class large displacement coaxial flow steering unit for better maneuverability

- Large interior space and excellent visibility on the integrally molded cab, and fresh air pressurization function for improved ventilation

Low Operating Cost

- Weichai Stage III engine and 2 adjustable power modes to meet different application needs

- Single load sensing hydraulic system supplies flow and pressure only when required, which saves fuel by 8%-12%

- Performance series bucket loads more and makes it easier to dig into the pile, therefore reducing fuel consumption

- Caterpillar split pump technology supplies oil separately to transmission and torque conver, resulting in 6% savings in fuel

Proven Reliability

- Highly reliable Caterpillar designed and manufactured electrohydraulic control transmission

- Smooth gearshift and self-protection function ensures durability of transmission

- SEM customized Weichai engine delivers optimal power and productivity

Ease of Maintenance

- Centralized lubrication points and optional automatic lubrication system to reduce maintenance time

- Pressure test ports for improved diagnosis and oil sampling

- long-span articulation design ensures ease of maintenance without additional space requirement on site

- Simple and reliable powertrain design to ensure low customer O&O (Owning & Operating) costs

- Wide angle engine hood for easy access to maintenance and service points

- 330L super-large fuel tank extends operating hours before refilling

Operational Safety

- Gear lock ensures that machine can only be started when it is in neutral

- Dual-circuit brake system and optional brake dryer to improve machine safety

- Three-point contact design when entering or exiting the equipment

- Maintenance-free battery, backup alarm and beacon light to ensure safety of operator

- Six front and four rear brake calipers for excellent braking performance and reduce risk of overheating

- Optional rear camera for enhanced visibility

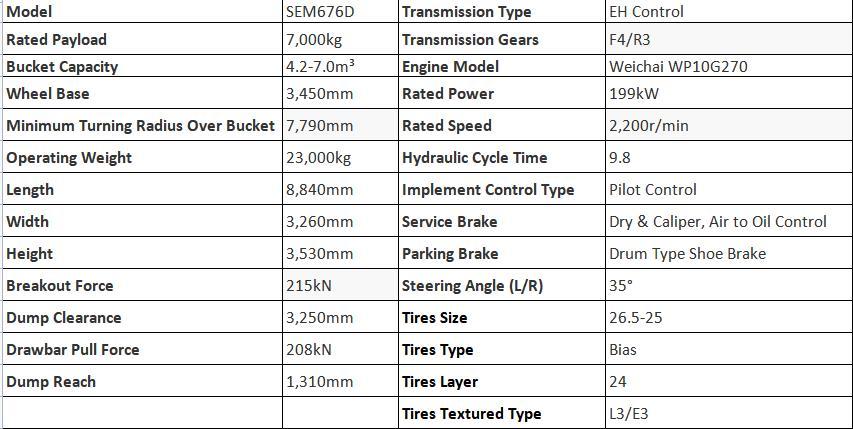

Specifications