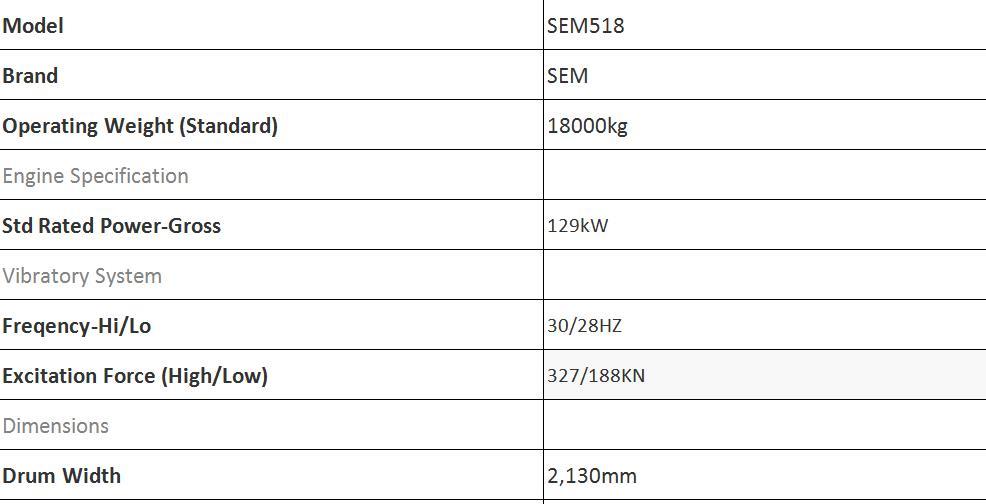

SEM518 Soil Compactor

- Model

- SEM518

Item specifics

- Operating weight

- 18000kg

- Std Rated Power-Gross

- 129kW

- Driving model

- Hydraulic type

- Origin

- China

Review

Description

SEM518

SEM518 SINGLE STEEL WHEEL ROLLER ADOPTS CATERPILLAR POD TYPE VIBRATION SYSTEM, CATERPILLAR DESIGNED DOUBLE ROW FOUR INDEPENDENT MODULE COOLING SYSTEM, STABLE AND RELIABLE, FAULT WARNING SYSTEM AT THREE LEVELS, OPTIMIZED DESIGN OF CAB, OPERATION MORE SAFE AND COMFORTABLE.

Powertrain

- Electronically controlled transmission

- to shift, reduces operator fatigue and improves working efficiency

- High reliability

- Axle equipped with Proportional Torque differential (PTD)

- PTD controls torque applied to the wheels based on ground conditions, improves overall traction

- Grade ability is 34% compared to competitors’ at 30%

- Optimized transmission ratio, 1st gear has higher travel speed

Dashboard

- Vibratory Frequency Meter

- Continuously displays machine compaction frequency

- Operator may select appropriate frequency to avoid excessive compaction

- Three Level Alarm System

- Machine will diagnose system issues and notify the operator with 3 levels of warning indicator lights and audio alarms

Key Features

- Application/Versatility

- Applications include road, railway, airfield and industry yard compaction

- Optional diamond shape pad-foot roller for compacting clay soils

- Optional square shape pad-foot roller for compacting sandy materials

- High efficiency

- 50mm drum, compaction performance is 10%~15% better than competitors

- Isolated modular cooling system, works in ambient temperature of 43 ℃

- Reliability

- Vibration system utilizes an eccentric vibe pod design, extends life up to 50%

- Closed center hydraulic system, world famous piston pump and motor

- Electronically controlled transmission, easy and

- Comfortable to operate

- Digital frequency meter, monitors compaction frequency

- Three level alarm system and Engine speed guage monitor machine performance

Tiltable Cab

- SEM offers a tiltable cabin which provides more convenient maintenance of the pump, transmission, hose and electronic components

- Hydraulic tiltable cab is optional

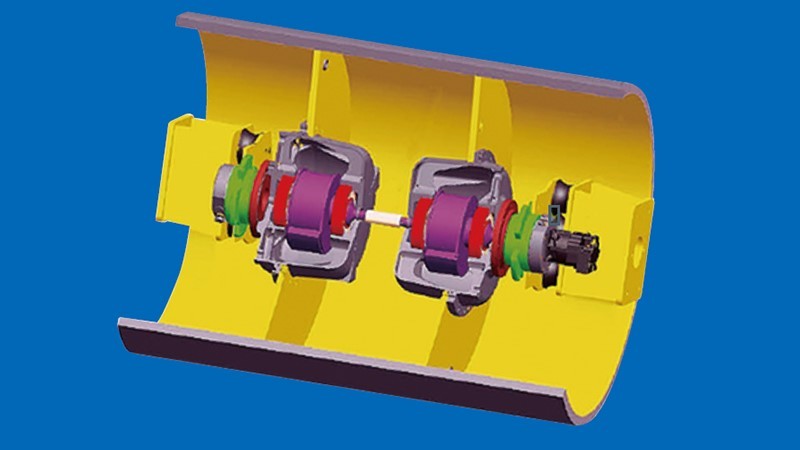

Vibe Pod Design

- Eccentric vibe pod design, extends system life by 50%

- Steel shot moving inside closed eccentric block, stable and reliable vibe amplitude, reduces impact to motor, prolongs maintenance period of vibratory system

- Completely sealed eccentric gear eliminates contamination, prolongs bearing life

Specifications